Our Vacuum ovens LVO are suitable for drying* of sensitive products, thermal treatments of oxidizable materials, quick drying of powders and granulate… in pharmaceutical, cosmetics, plastics, electronics, chemical, agrifood… laboratories or industries.

* For any drying application, please contact us to explain exactly your need to info@plasmadiam.com. We will help you to find the products adapted to your needs.

Max temperature : 200°C**

** We can make vacuum ovens above 200°C, consult us !

Vacuum range : from 0 to -1000 mbar (relative pressure)

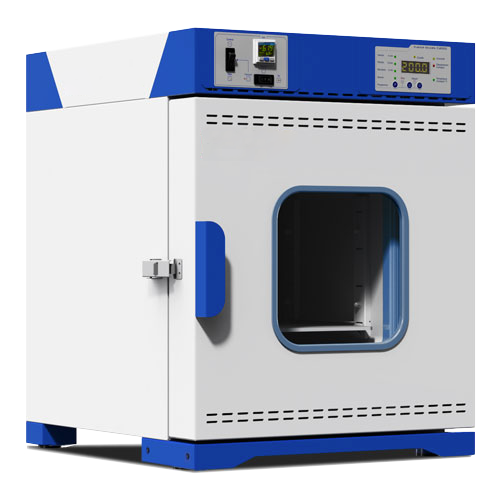

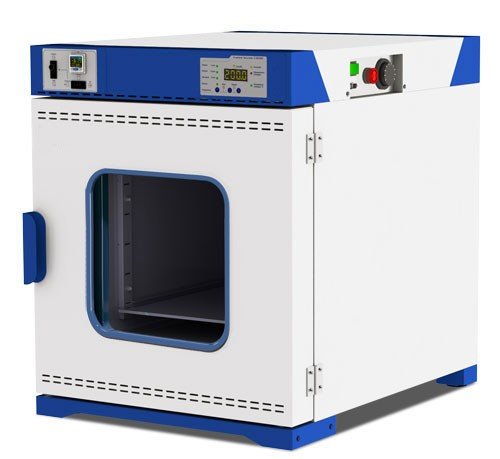

Exterior made of steel coated with blue and white epoxy paints The inner casing is made of corrosion resistant strong thick stainless steel.

THICK INSULATION

No contact between the inner and outer casings for no thermal bridge. Insulation is made of asbestos-free glass wool : low surface temperature, low electrical consumption, a rapid rise in temperature.

DOOR WITH VIEWING WINDOW

The door is equipped with a thick safety glass.

SEALING

A silicone gasket provides the seal of the door. It may be replaced by a viton seal (optional). Closing the door by adjustable clamps.

EASY CLEANING

The rounded corners of the inner casing make easier cleaning operations ; the racks and the seal are easy-to-remove.

Heating is ensured by heating elements located on outer faces of the inner casing for the best homogeneity.

Note : the temperature sensor is fastened on the wall inside the oven. Therefore, there is a difference between the temperature on the tray and that displayed on the temperature controller of the oven.

Vacuum ovens LVO feature a DN16KF passage with a silicone plug. It is possible to introduce up to 4 temperature sensors for temperature measurements inside the oven.

An easy connection of your vacuum pump.

The electrical connection of the vacuum pump is made directly to the back of the oven. Teats allow the pumping of air and vacuum breaking (LVO-020 and LVO-050). From LVO-120 model, pumping connector type is KF.

The electrical connection of the vacuum pump is made directly to the back of the oven. Teats allow the pumping of air and vacuum breaking (LVO-020 and LVO-050). From LVO-120 model, pumping connector type is KF.

The C3000 temperature controller is a highly accurate and highly reliable microprocessor. Very efficient and extremely easy to use. Measurement by PT100 sensor. PID electronic regulator. Accuracy: 0.1°C.

Functions :

• Setpoint display and that measured.

• Delayed Start : 1min to 99h59min.

• Heat ramp.

• Heating timer from 0 to 99h59min.

• Repeat loop.

• Buzzer at the end of a cycle.

• Over temperature alarm.

+41 (0)32 926 26 06

info@plasmadiam.com

Jambe-Ducommun 19 – 2400 Le Locle