MVO vacuum ovens are suitable for sensitive product drying applications*, outgassing, thermal treatments of oxidizable materials, quick drying of powders and granulates. For any drying application, please contact us to explain exactly your need to info@plasmadiam.com. We will help you to find the products adapted to your needs.

The outside of the vacuum ovens is made of steel covered with white and blue epoxy paint. The inner casing is made of corrosion resistant stainless steel.

THICKNESS ISOLATION

The outer casing is separated from the inner casing to prevent any loss of heat. Non-asbestos insulation allows low surface temperatures, reduced power consumption and rapid temperature rise.

DOOR WITH VIEWING WINDOW

Thick safety glass window which avoid overpressure.

SEALING

The seal on the door is guaranteed by a long-life silicone gasket. It can be replaced with a viton seal (option). Locking by adjustable clamps

EASY CLEANING

Rounded corners and removable racks allow easy cleaning.

Heating is ensured by heating elements located on outer faces of the inner casing for best homogeneity.

MVO vacuum ovens have 2 temperature sensors : 1 probe fastened on the side, 1 other is mobile to be integrated on your product. The controller automatically adjusts the temperature of the walls for a perfect precision on your products.

The ovens are controlled by a 5.7″ color touch screen controller. Very intuitive and easy to use.

TEMPERATURE CONTROL

Automatic control and real-time monitoring of temperature measured by a thermocouple probe J.

VACUUM CONTROL

High precision PID control. Several modes of vacuum regulation are possible : maximum vacuum level of the pump; maintaining a constant pressure. Automatic control of solenoid valves for changing the vacuum level. Real-time monitoring of vaccum level.

HISTORY OF TREATMENTS

A USB port is used to store process data (vacuum temperatures and vacuum levels). These values can only be used by the controller.

Note : The oven can be controlled via a PC with an RJ45 cable.

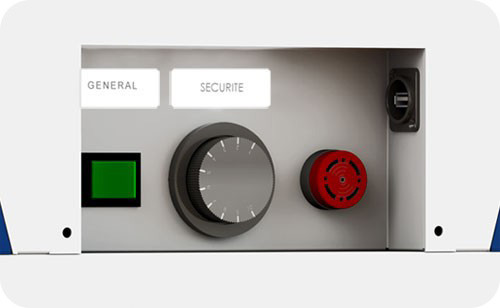

An adjustable and non-resettable mechanical thermostat (class 3.1 protection) protects the oven / product against overheating. It measures the temperature in the volume, and supports the regulation in case of failure of the temperature controller.

It stops heating until the temperature has dropped below the value of its setting. With visual and audible alarm.

The controller has an additional alarm function that follows the setpoint temperature of your oven. At any time, when the measured temperature exceeds 5°C, the power circuit of the oven is cut.

+41 (0)32 926 26 06

info@plasmadiam.com

Jambe-Ducommun 19 – 2400 Le Locle