Plus larger capacities if combined with Roots Boosters

Increased productivity and product quality

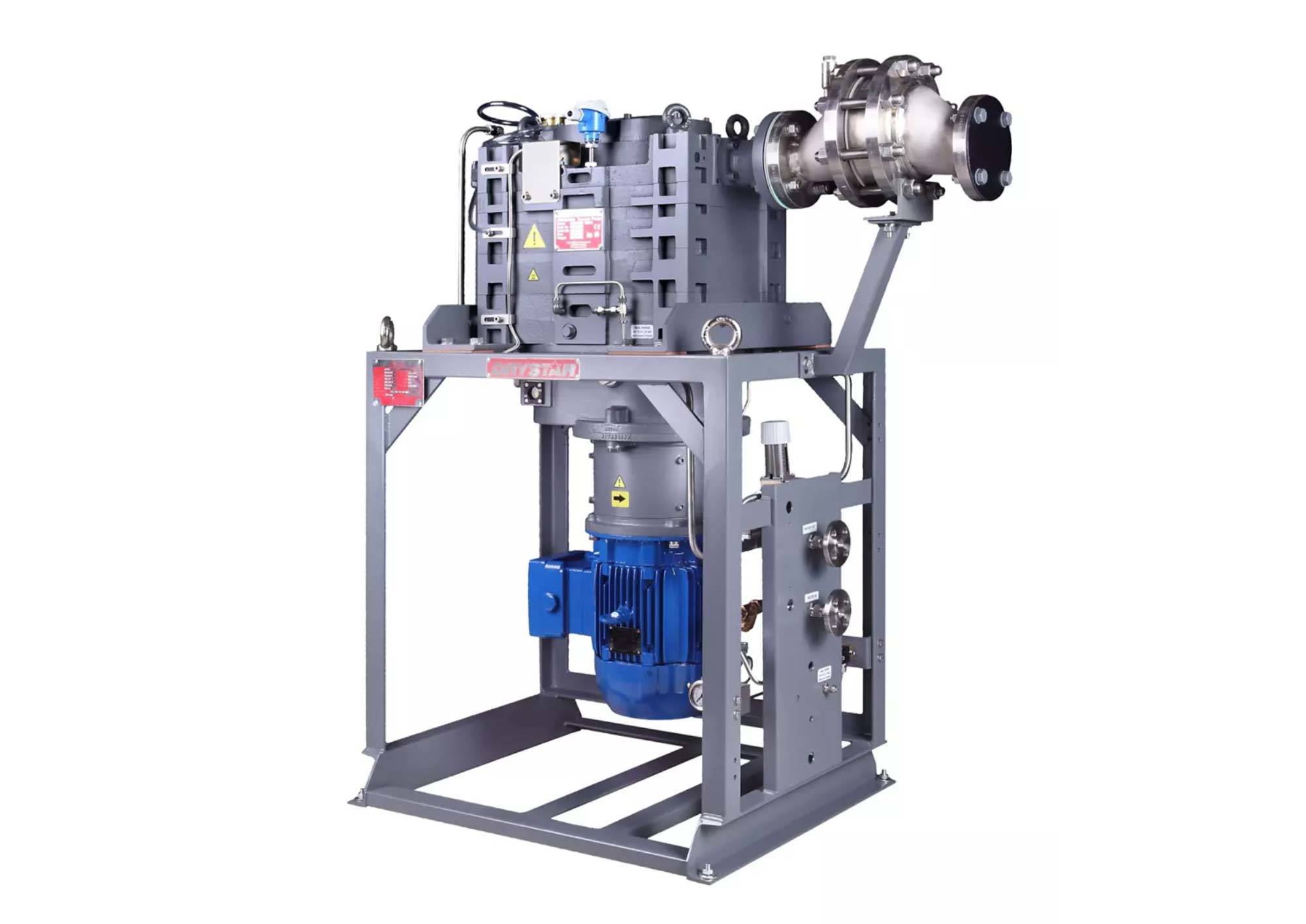

Specifically designed for chemical applications

Stable operation, even during process upsets

Easy maintenance, low utilities consumption and no cooling gas injection required

| Units | EDP80 | EDP160 | EDP250 | EDP400 | |||||

|---|---|---|---|---|---|---|---|---|---|

| 50 Hz | 60 Hz | 50 Hz | 60 Hz | 50 Hz | 60 Hz | 50 Hz | 60 Hz | ||

| Maximum pumping speed | m³h4 | 83 | 102 | 163 | 202 | 260 | 320 | 377 | 427 |

| ft³min4 | 49 | 60 | 96 | 119 | 153 | 188 | 222 | 251 | |

| Capacity at 10 mbar (7.5 Torr) | m³h4 | 75 | 102 | 153 | 198 | 255 | 315 | 377 | 422 |

| ft³min4 | 44 | 60 | 90 | 117 | 150 | 185 | 222 | 248 | |

| Ultimate vacuum | mbar | 0.5 | 0.3 | 0.5 | 0.3 | 0.5 | 0.2 | 0.4 | 0.2 |

| Torr | 0.4 | 0.2 | 0.4 | 0.2 | 0.4 | 0.2 | 0.3 | 0.2 | |

| Maximum back pressure – standard (optimal*) | mbarA | 1150 (1300*) | 1150 (1300*) | 1150 (1300*) | 1150 | ||||

| psig | 2.2 (4.4*) | 2.2 (4.4*) | 2.2 (4.4*) | 2.2 | |||||

| Power consumption at 10 mbar (7.5 Torr) | kW | 3.3 | 4.0 | 4.9 | 4.9 | 6.0 | 6.0 | 7.0 | 7.0 |

| hp | 4.4 | 5.4 | 6.6 | 6.6 | 8.0 | 8.0 | 9.4 | 9.4 | |

| Standard motor (380 – 400, 3 ph, 50 Hz) | kW | 5.5 | 5.5 | 7.5 | 11.0 | 11.0 | 15.0 | 18.5 | 25.0 |

| Standard motor (380 – 400, 3 ph, 60 Hz) | hp | 7.5 | 7.5 | 10.0 | 15.0 | 15.0 | 20.0 | 25.0 | 30.0 |

| Cooling water flow rate (adjustable) | l min4 | 1 – 8 | 1 – 10 | 1 – 8 | 1 – 10 | 1 – 10 | 1 – 10 | 1 – 10 | 1 – 10 |

| gal min4 | 0.3 – 2.1 | 0.3 – 2.6 | 0.3 – 2.1 | 0.3 – 2.6 | 0.3 – 2.6 | 0.3 – 2.7 | 0.3 – 2.6 | 0.3 – 2.7 | |

| Cooling water supply pressure | barg | 2 – 10 | |||||||

| psig | 29 – 145 | ||||||||

| Seal purge flow (maximum), regulated to 0.3 – 0.5 barg (5 – 7 psig) | l min4 | 20 | |||||||

| ft³ min4 | 0.7 | ||||||||

| Seal purge supply pressure (minimum – maximum) | barg | 2 – 10 | |||||||

| psig | 29 – 145 | ||||||||

| Noise (maximum with exhaust silencer) | dB(A) | 73 | 73 | 77 | 78 | 79 | 79 | 82 | 82 |

| Weight (with frame and standard motor) | kg | 648 | 650 | 747 | 756 | 848 | 860 | 918 | 960 |

| lbs | 1429 | 1433 | 1647 | 1667 | 1870 | 1909 | 2024 | 2116 | |

| Process connection, inlet | ANSI/DIN | 2″/DN50 | 3″/DN80 | 3″/DN80 | 3″/DN80 | ||||

| Process connection, outlet | ANSI/DIN | 1.5″/DN40 | 1.5″/DN40 | 2″/DN50 | 2″/DN50 | ||||

| Pumping mechanism | 3 stage reversed claw | ||||||||

| *Consult Edwards | |||||||||

+41 (0)32 926 26 06

info@plasmadiam.com

Jambe-Ducommun 19 – 2400 Le Locle