TSPs can operate from 10-5 to 10-12 mbar and have pumping speeds in excess of 10,000 m3/h of hydrogen.

Can be used independently or in combination with ion pumps to remove reactive gases from the vacuum environment

All TSP components are bakeable to 400°C

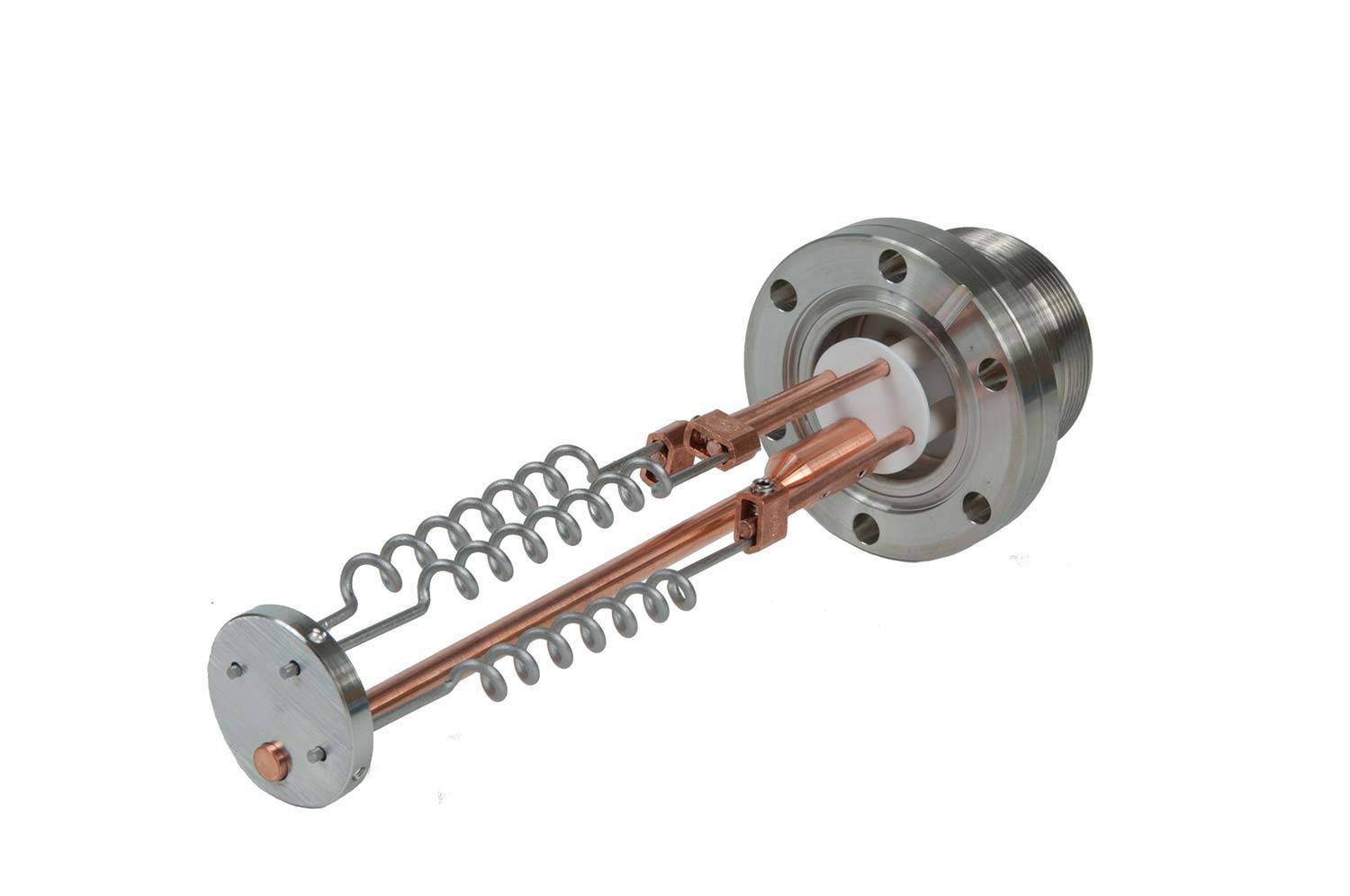

Titanium Sublimation Pumps (TSPs) are often used in combination with ion pumps or independently to remove reactive gases from the vacuum environment.

Combined with an ion pump, the TSP allows for low ultimate pressures in a shorter amount of time. All TSP components are bakeable to 400°C.

TSPs operate by heating a titanium filament and subliming (converting from solid to gas phase) titanium molecules onto a surface. Sublimed titanium molecules are then available to chemically react with reactive gases, like oxygen and nitrogen, and disassociate and diffuse hydrogen. TSPs can operate from 10-5 to 10-12 mbar and have pumping speeds in excess of 10,000 m3h-1 of hydrogen.

Mechanical vibration eliminated

capture pumps have no moving parts. Vibration from moving parts and electrical noise is eliminated

High radiation tolerance

capture pumps are built with radiation tolerant materials in excess of 108 Gray. Connectors and cables are also built with radiation tolerant materials for years of continuous operation

High temperature tolerance

without any special consideration, capture pumps can be baked to 250 °C. Removing the magnets allows for hotter bakes up to 450 °C. Long hot bakes are critical to every UHV system

Regular maintenance eliminated

capture pumps require virtually no maintenance and avoid costly vacuum events because they are sealed from atmosphere, saving time, money and resources

Low initial operational costs

initial cost is typically less than comparable specifications of other types of vacuum pumps. They use minimal or no power for years of low cost operation

+41 (0)32 926 26 06

info@plasmadiam.com

Jambe-Ducommun 19 – 2400 Le Locle